Презентация на тему: Orbitron Project. New low-cost launch vehicles

Space Cargoes Low-Cost Delivery Method Orbitron Project Alexander Mayboroda AVANTA Consulting

Space Cargoes Delivery Problems Prices to deliver cargo into space are high. The cost of satellite launching to geostationary orbit (GEO) amounts to $50 000 USD/kg. It is necessary for business development of space to reduce prices to 5-10% of current ones.

Space Cargoes Delivery Problems To reduce prices it is essential for the planet protection from various space menaces.

Market Prospects Launching services market is growing. In 2013 the make size reached $5.4 billon*. In case of unit cost reduction by 10 times, annual profits of launching companies will amount to $ 5 billion. *) According to Satellite Industry Association (SIA) information on telecommunication, space and satellite industries revenues between 2001 and 2013.

Attempts to solve the problem are aspirations to create reusable space vehicles and to reduce prices by decreasing spacecraft depreciation & amortization expenses. Attempts to solve the problem are aspirations to create reusable space vehicles and to reduce prices by decreasing spacecraft depreciation & amortization expenses. Unfortunately, such projects are long overdue; and single use rockets (expendable spacecraft) are still being launched.

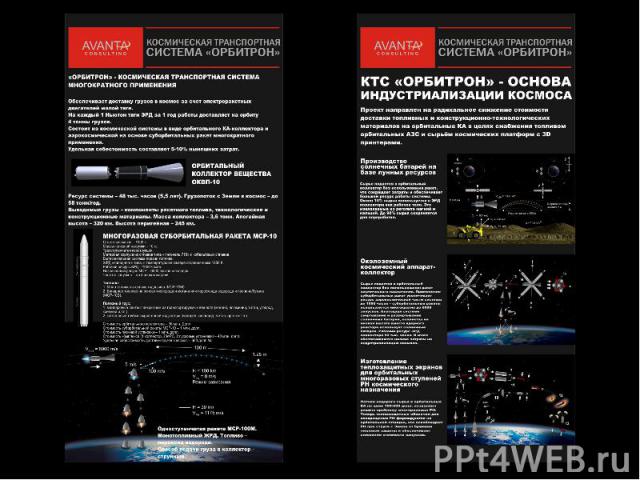

Solution The ORBITRON Project solves the problem of reusable space vehicles creation.

Solution The prototype project is an US patent (US4775120 & US5199671), unimplemented because of the spacecraft huge mass of 40 000 tons.

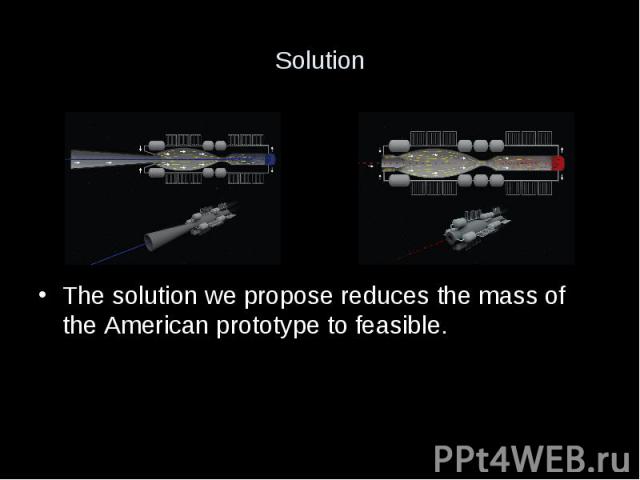

Solution The solution we propose reduces the mass of the American prototype to feasible.

Orbitron, Orbital Substance Collector (OSC) The developed space vehicle system consists of two parts: The first part is an aerospace (land based) part based on suborbital rockets; The second part is an orbital cargo satellite collector.

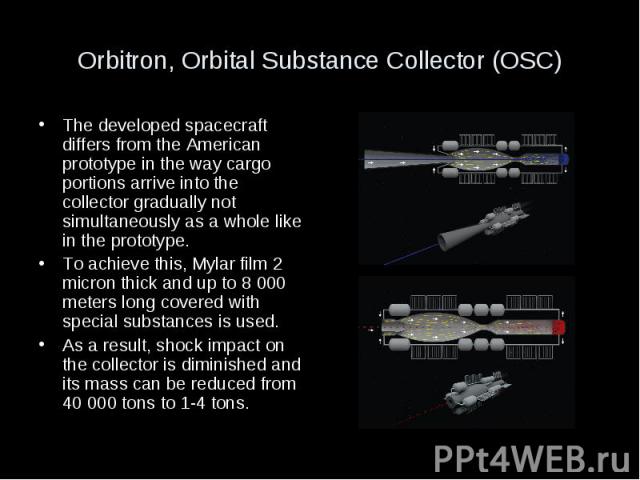

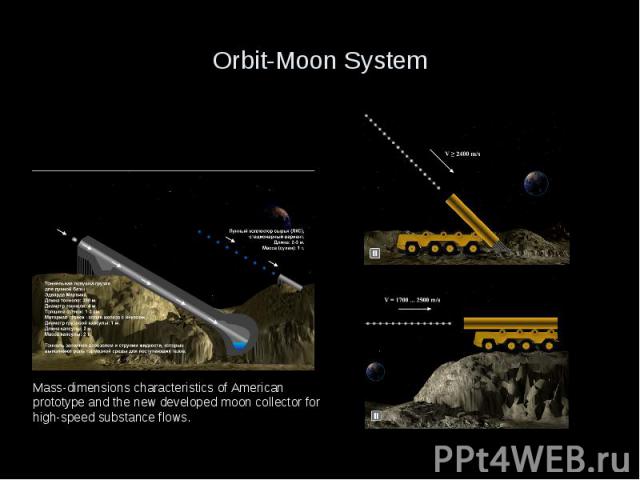

Orbitron, Orbital Substance Collector (OSC) The developed spacecraft differs from the American prototype in the way cargo portions arrive into the collector gradually not simultaneously as a whole like in the prototype. To achieve this, Mylar film 2 micron thick and up to 8 000 meters long covered with special substances is used. As a result, shock impact on the collector is diminished and its mass can be reduced from 40 000 tons to 1-4 tons.

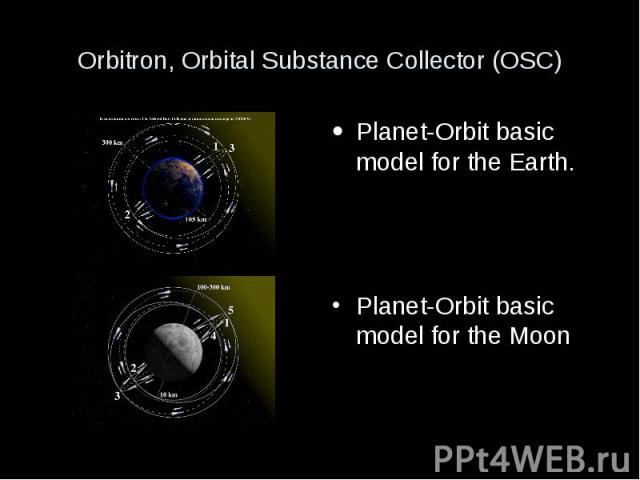

Orbitron, Orbital Substance Collector (OSC) Planet-Orbit basic model for the Earth. Planet-Orbit basic model for the Moon

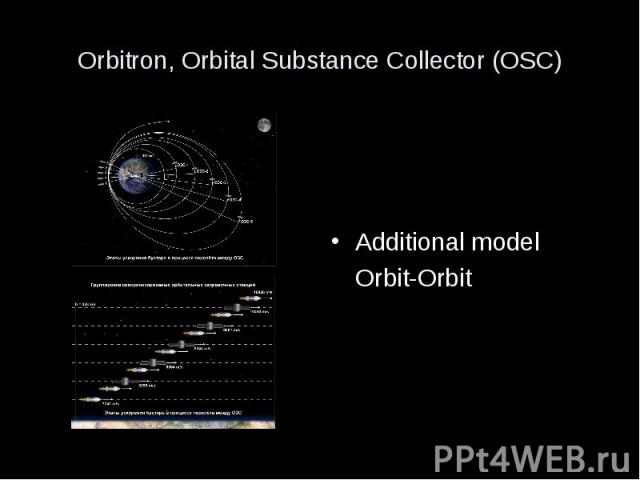

Orbitron, Orbital Substance Collector (OSC) Additional model Orbit-Orbit

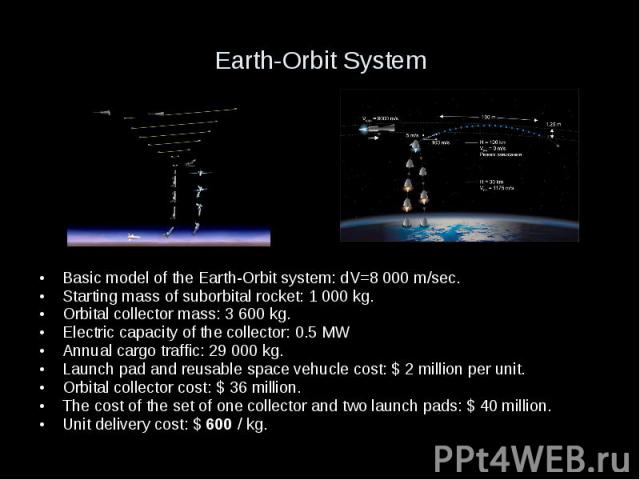

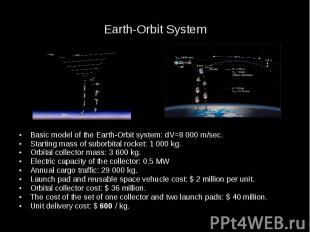

Earth-Orbit System Basic model of the Earth-Orbit system: dV=8 000 m/sec. Starting mass of suborbital rocket: 1 000 kg. Orbital collector mass: 3 600 kg. Electric capacity of the collector: 0.5 MW Annual cargo traffic: 29 000 kg. Launch pad and reusable space vehucle cost: $ 2 million per unit. Orbital collector cost: $ 36 million. The cost of the set of one collector and two launch pads: $ 40 million. Unit delivery cost: $ 600 / kg.

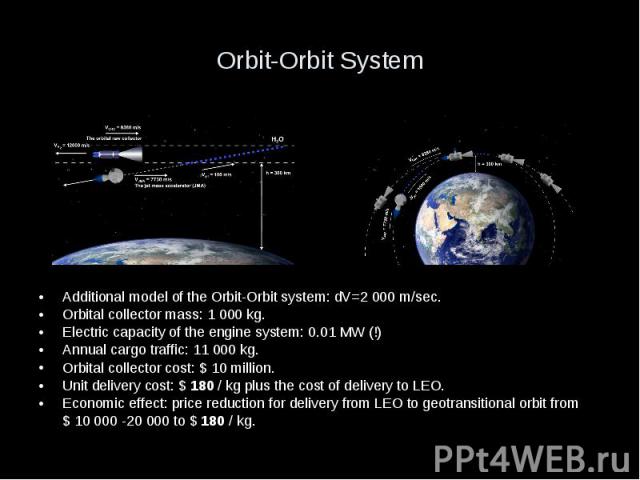

Orbit-Orbit System Additional model of the Orbit-Orbit system: dV=2 000 m/sec. Orbital collector mass: 1 000 kg. Electric capacity of the engine system: 0.01 MW (!) Annual cargo traffic: 11 000 kg. Orbital collector cost: $ 10 million. Unit delivery cost: $ 180 / kg plus the cost of delivery to LEO. Economic effect: price reduction for delivery from LEO to geotransitional orbit from $ 10 000 -20 000 to $ 180 / kg.

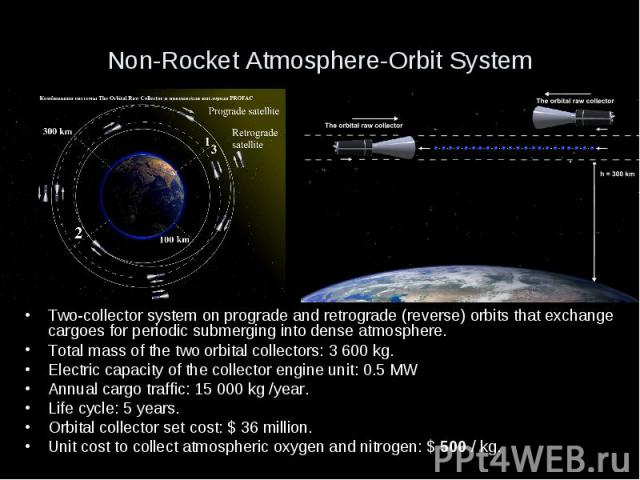

Non-Rocket Atmosphere-Orbit System Two-collector system on prograde and retrograde (reverse) orbits that exchange cargoes for periodic submerging into dense atmosphere. Total mass of the two orbital collectors: 3 600 kg. Electric capacity of the collector engine unit: 0.5 MW Annual cargo traffic: 15 000 kg /year. Life cycle: 5 years. Orbital collector set cost: $ 36 million. Unit cost to collect atmospheric oxygen and nitrogen: $ 500 / kg.

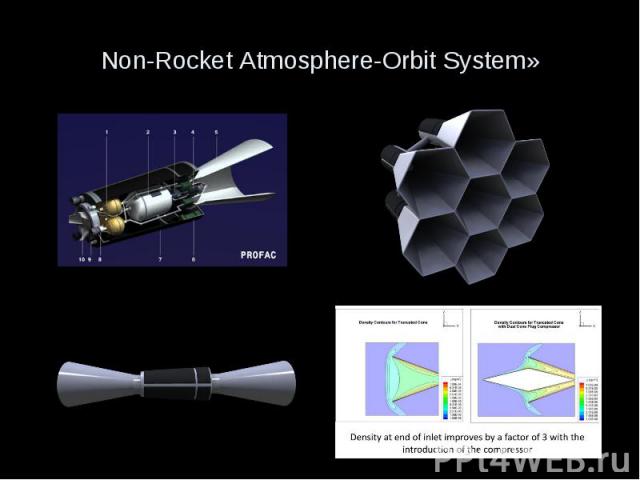

Non-Rocket Atmosphere-Orbit System»

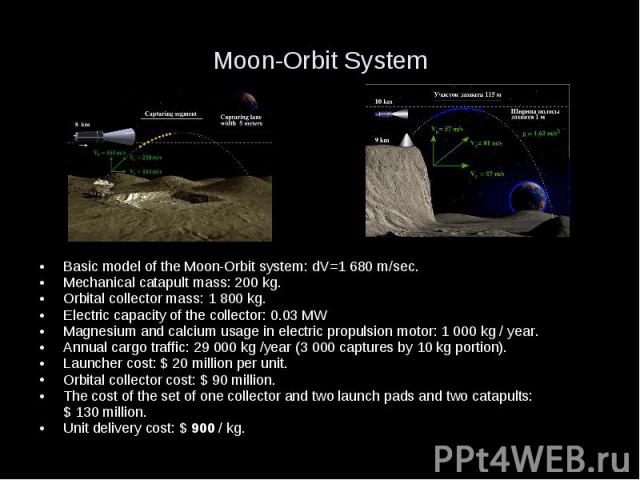

Moon-Orbit System Basic model of the Moon-Orbit system: dV=1 680 m/sec. Mechanical catapult mass: 200 kg. Orbital collector mass: 1 800 kg. Electric capacity of the collector: 0.03 MW Magnesium and calcium usage in electric propulsion motor: 1 000 kg / year. Annual cargo traffic: 29 000 kg /year (3 000 captures by 10 kg portion). Launcher cost: $ 20 million per unit. Orbital collector cost: $ 90 million. The cost of the set of one collector and two launch pads and two catapults: $ 130 million. Unit delivery cost: $ 900 / kg.

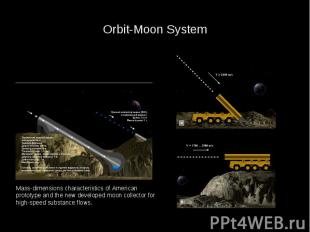

Orbit-Moon System

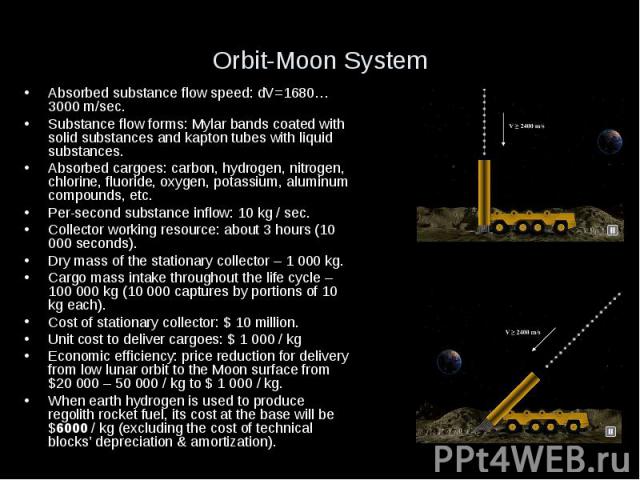

Orbit-Moon System Absorbed substance flow speed: dV=1680…3000 m/sec. Substance flow forms: Mylar bands coated with solid substances and kapton tubes with liquid substances. Absorbed cargoes: carbon, hydrogen, nitrogen, chlorine, fluoride, oxygen, potassium, aluminum compounds, etc. Per-second substance inflow: 10 kg / sec. Collector working resource: about 3 hours (10 000 seconds). Dry mass of the stationary collector – 1 000 kg. Cargo mass intake throughout the life cycle – 100 000 kg (10 000 captures by portions of 10 kg each). Cost of stationary collector: $ 10 million. Unit cost to deliver cargoes: $ 1 000 / kg Economic efficiency: price reduction for delivery from low lunar orbit to the Moon surface from $20 000 – 50 000 / kg to $ 1 000 / kg. When earth hydrogen is used to produce regolith rocket fuel, its cost at the base will be $6000 / kg (excluding the cost of technical blocks’ depreciation & amortization).

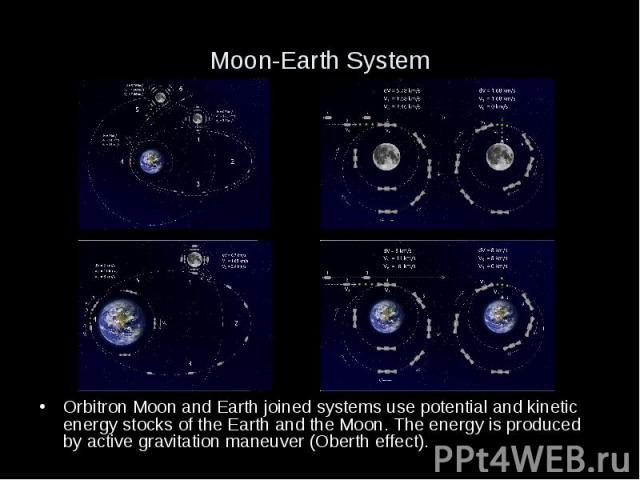

Moon-Earth System Orbitron Moon and Earth joined systems use potential and kinetic energy stocks of the Earth and the Moon. The energy is produced by active gravitation maneuver (Oberth effect).

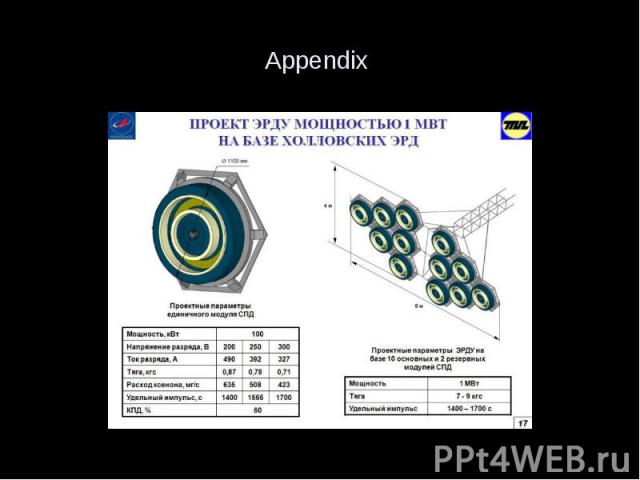

Resources for Suborbital Subsystem and Orbital Collector Suborbital rockets, alternatively to space rockets, survive the first launch and are reusable for 200-1 000 launches. In the project we use the solution that allows reusing suborbital rockets from 1 000 to 6 000 launches: temperature in combustion chamber does not exceed 1 250 K. The orbital collector engines of NEXT or VASIMR type possess long life cycle of about 50 000 hours or 5.5 years.

Resources for Suborbital Subsystem and Orbital Collector Heat protection of rocket stages excluding its first stage is executed similar to that of X-20 Dyna-Soar rocketplane with radiative cooling made of refractory metals and alloys (molybdenum, zirconium, rhenium-niobium alloy Rene 41) without ablation or heat-absorbing ceramic coating. This type of heat protection ensures minimal time for its routine maintenance after the landing of suborbital rocket and its long life cycle. Due to the extended repair interval for heat protection and the engine, the launch frequency for the suborbital rocket is from four to eight launches per day.

Resources for Suborbital Subsystem and Orbital Collector Analogue to the Bullet Catcher orbital collector. Bullet traps do not deform bullets: dV up to 1100 m/sec; Kevlar deceleration environment resource is 10 000 shots. Bullet traps of solid deceleration are filled with water/sand and prove to have practically unlimited life cycle; their dV lies between 8 000 and 11 000 m/sec. To prevent emergency collisions Armour Screen is used; it is made of such materials the sound speed of which is between 13 000 and 18 000 м/с. The 3D printer on board compensates Armour Screen erosion.

Types of Cargoes The collector can receive cargoes of only raw material type that are not destroyed by impact acceleration. However, most cargoes delivered into space are not spacecraft but rocket fuel to set them into the final orbit. Up to 80% of the spacecraft’s weigh is the mass of its fuel. Therefore, the proposed space vehicle system will have many types of cargoes.

Types of Cargoes In addition to fuel, such substances as aluminum, titanium, carbon, silicon and other necessary substances are to be transported into space to produce spare parts and units for spacecraft in the framework of AMAZE program. European Space Agency (ESA) has launched AMAZE program to apply 3D printing technology for production of metallic parts and units for spacecraft, airplanes and thermonuclear reactors; ESA has invested about € 20 million into R&D to create AMAZE 3D Printing Technology.

Orbitron Technology Business Opportunities The technology implementation allows its users to create: A chain of space fueling stations to fuel inter-orbital boosters and tugs; A chain of orbital platforms with 3D printers to produce spare parts and units for spacecraft.

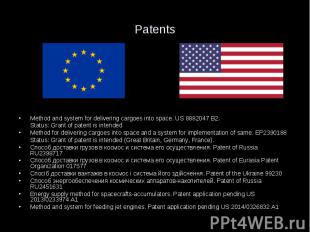

Patents Method and system for delivering cargoes into space. US 8882047 B2. Status: Grant of patent is intended Method for delivering cargoes into space and a system for implementation of same. EP2390188 Status: Grant of patent is intended (Great Britain, Germany, France). Способ доставки грузов в космос и система его осуществления. Patent of Russia RU2398717 Способ доставки грузов в космос и система его осуществления. Patent of Eurasia Patent Organization 017577 Спосіб доставки вантажів в космос і система його здійснення. Patent of the Ukraine 99230 Способ энергообеспечения космических аппаратов-накопителей. Patent of Russia RU2451631 Energy supply method for spacecrafts-accumulators. Patent application pending US 2013/0233974 A1 Method and system for feeding jet engines. Patent application pending US 2014/0326832 A1

Patents

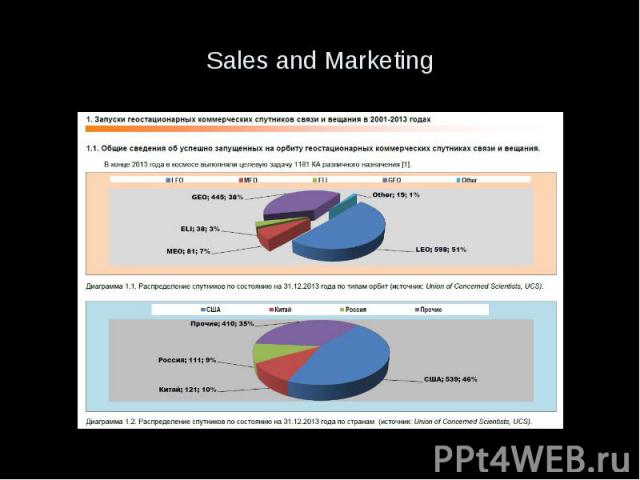

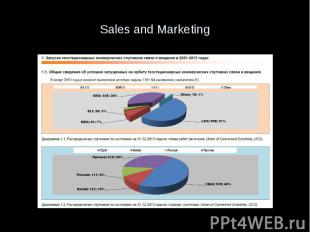

Sales and Marketing

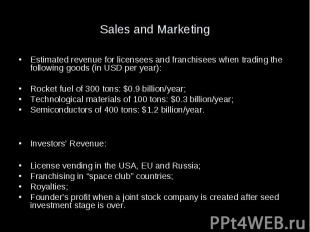

Sales and Marketing Estimated revenue for licensees and franchisees when trading the following goods (in USD per year): Rocket fuel of 300 tons: $0.9 billion/year; Technological materials of 100 tons: $0.3 billion/year; Semiconductors of 400 tons: $1.2 billion/year. Investors’ Revenue: License vending in the USA, EU and Russia; Franchising in “space club” countries; Royalties; Founder’s profit when a joint stock company is created after seed investment stage is over.

Market segments Launch Services market: $ 5 billion / year; Spacecraft and satellites production market, spacecraft being produced on the orbit using AMAZE program: $16 billion/year

Market segments Photoelectric converters market: $ 100 billion / year; Including thin-film solar batteries: $25 billion / year.

Market segments Raw material supply market for satellite solar power station construction in the framework of the Japanese Solarbird program: $24 billion.

Market segments Material delivery market to construct and maintain Lunar Base in the framework of the Russian program (patents granted until 2030): Construction: $ 40 billion Supplies to the base: $ 4-15 billion / year.

Competitors Shackleton Energy Company, USA, working on water-production technologies on the Moon to produce oxygen and hydrogen to sell them via orbital fueling stations. PHARO start-up, USA, developing PROFAC system with laser energy drive to collect atmospheric oxygen in order to produce fuel for space fueling stations.

Potential Partners Planetary Resources Deep Space Industries SpaceX Bigelow Aerospace Boeing Company EADS Astrium MDA Mitsubishi Corp. Shimizu Corp. TSNIIMASH (Central Scientific Research Institute of Machine Building): orbital space vehicle air collectors and frameless solar batteries Institute for Space Research of the Academy of Sciences: Spacecraft mathematic models United Institute а High Temperatures: Mathematic models for shock and impact processes

Potential Partners Institute of Semiconductor Physics of Siberian Department of Russian Academy of Sciences and Russian Space Agency: ОКА-Т technological module Moscow State Technical University named after N.E. Bauman: EDTS cable electric engine State Space Research and Production Center named after M. Khrunichev: MRKC-1 suborbital demonstrator Design Engineering Department for Chemical Automation: YARD Thermal-chemical simulator /Nuclear thermal rocket / State Scientific Center named after Keldysh: heating exchange hydrogen engine unit for solar heat rocket engine Lin Industrial Company: suborbital mini launch rockets

Ideal of the Project: Alexander Mayboroda Ideal of the Project: Alexander Mayboroda Project Manager: Vladimir Megel Leading Specialists: D.K. Dragun, V.M. Melnikov, O.P. Pchelyakov, V.I. Florov Main participants and their skills: the team has ten specialists with necessary qualifications, knowledge and experience. Among them, there are specialists of TSNIIMASH, Vympel Design Engineering Department, Moscow State Technical University named after N.E. Bauman, Institute for Space Research of the Academy of Sciences, Institute of Semiconductor Physics of Siberian Department of Russian Academy of Sciences, Sputniks Company.

Team

R&D First Stage Investment Stages of the working process: Conceptual Design Studies; Computer Simulation of the Processes; Collector Demo Model Creation, its bed testing, follow-up revision; Production of collector in micro-satellite version for orbital tests (dV=1400-2000 m/sec), follow-up revision; Resources required: 40 million rubles (including 10 million rubles from a private investor and 30 million rubles from Scolkovo Fund) First stage lasts for two years. Keeping the US and EU patents and completion of new patents obtaining process require: $ 11 000 in 2015; $ 5 000 in 2016.

Summary and Contacts The developed system ensures radical cost decrease for space cargoes delivery. Cost efficiency provides extra profit in the sphere of raw material space cargoes delivery to orbital spacecraft. We are looking for commercial partners and investors to continue the project. AVANTA Consulting welcomes you to collaborate in commercialization of Orbitron Project. Address: 150 Bolshaya Sadovaya Street, suite 909, Rostov-on-Don, 344000, Russia. Ph.: +7 (863) 221 73 71; +7 (863) 263 32 94 Email: [email protected] URL: www.mayboroda.com Thank you for your attention Your questions are welcome

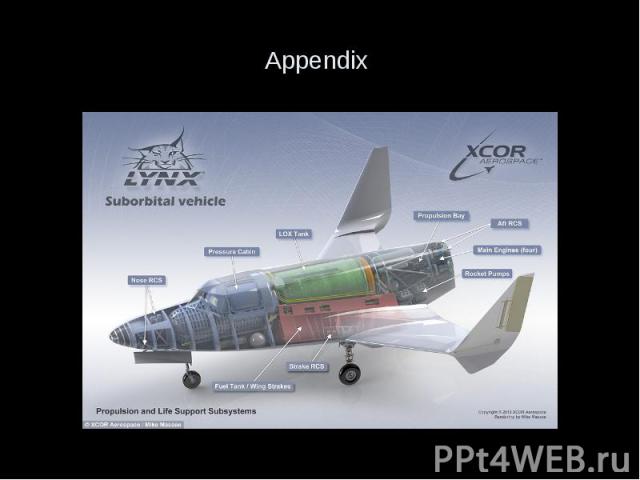

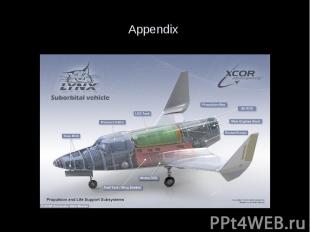

Appendix

Appendix

Appendix

Appendix